In addition to cutting food, it can be used in a variety of situations, such as clearing grass and branches, making firewood, and stabbing and dismantling prey during hunting.

There are various types of knives on the market, but custom knives made by the creators who make full use of their knowledge and experience are especially appealing.

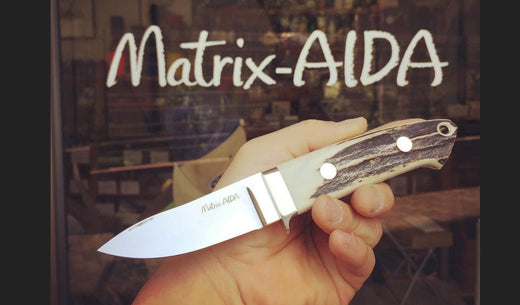

This time, I visited Musashino Kinzoku Kogyosho (store name: Matrix Aida) in Narimasu, Itabashi-ku to hear about custom knives.

Mr. Yoshimasa Aida, president of Musashino Metal Industry Co., Ltd., on the right side of the photo, and Mr. Toki Aida, a staff member on the left side.

Mr. Yoshimasa Aida, president of Musashino Metal Industry Co., Ltd., on the right side of the photo, and Mr. Toki Aida, a staff member on the left side. Despite his busy schedule, he spared time for the knife amateurs of the Inohoi editorial department and kindly taught us about custom knives.

First of all, what is a custom knife?

In a nutshell, it's a handmade knife.Custom-made knife builders make from scratch according to the user's needs, purpose, and concept.

How custom knives are made

There are two methods of manufacturing custom knives: forging, which is the same as for Japanese swords, and the stock and removal (S&R) method, which is currently the mainstream.forging

In this method, the voids inside the metal are crushed by hitting the heated metal with a hammer or the like to apply pressure, thereby increasing the strength and molding it into the desired shape.This method has been used for manufacturing cutlery and hardware since ancient times, and requires relatively large-scale equipment such as furnaces, hammers, press machines, and grinders.

Stock & Removal Law (S&R Law)

Originally, forging was the main method of manufacturing knives, but in the 1950s, Robert Waldorf Lovelace cut steel materials, created a prototype, and filed the stock and removal method as a more efficient method of manufacturing knives. devised.Since then, the Stock & Removal method has become the most common method of making custom knives around the world today.

Robert Waldorf Lovelace (Bob Lovelace or RW Lovelace)

As mentioned above, Mr. Lovelace devised the S&R method, but he seems to have devised the S&R method by creating a knife from the plate spring used for parts of American cars at that time.The high-quality knives made by Mr. Lovelace were used by famous adventurers around the world, including Ernest Hemingway.

And Mr. Lovelace's disciple is Mr. Yoshihito Aida (the younger brother of President Yoshimasa Aida), a leading knife builder in Japan.

Matrix Aida has many works by Mr. Lovelace, Mr. Yoshito Aida, and other famous builders, and even I, a knife amateur, felt a sense of exhilaration.

Above is a work by RW Lovelace.

Above is a work by RW Lovelace.I wonder if it's a fan coveted gem. . .

When you enjoy the outdoors, having your favorite knife by your side is even more fun.

Prepare a bonfire with a custom knife made from the ground up and sip a glass of whiskey in front of the bonfire. It's the dream of every boy who loves the outdoors.

custom knife steel

Various knife steels were placed in Matrix Ida.All knife steel is hard enough to be filed, cut with a metal hacksaw, and drilled.

After shaping the blade, it goes through a series of heat treatment processes such as quenching, and the steel becomes hard and durable as it breathes life into it as a knife.

kydex

Kydex is a popular material for knife sheaths. A thermoplastic synthetic resin plate that is light, strong, and waterproof.Ideal for knives in wet environments such as diving knives. In addition, it seems that it is also used for gun holsters for survival games.

Equipment for making custom knives

Matrix Aida also had knife making machines for sharpening as well as basic tools for making custom knives.Below is a picture of the Barking Knife Making Machine. This single machine does most of the necessary cutting and polishing work.

The appeal of custom knives

In time immemorial, mankind discovered the use of stone as a cutlery and used it as a knife.Over time, stone became bronzeware, then ironware, and stainless steel was invented.The materials and construction of knives have made dramatic progress along with the history of mankind.

The fact that many people are still fascinated by knives today may be due to the exhilaration that has been engraved in human DNA since ancient times.

In addition, at the Inohoi online shop , Matrix Aida also handles knives for stabbing and custom knife introductory kits .

In addition, at the Inohoi online shop , Matrix Aida also handles knives for stabbing and custom knife introductory kits .Please feel free to contact us.

Musashino Metal Industry

Established in 1914 (Taisho 3). Since our founding, we have been producing all kinds of cutting tools that match the times and markets, such as scissors, safety razors, nail clippers, and sapphire nail files, all at our own factory for 99 years.Known as one of the world's top custom knife manufacturers, they not only manufacture high-end custom knives, but also provide materials, machines, and tools to people who want to make knives all over the country.

access

Address: 2-26-18 Narimasu, Itabashi-ku, Kyoto Casa Yell 1F5 minutes walk from the south exit of Narimasu Station on the Tobu Tojo Line. * Behind the Daiei Narimasu store.

Homepage: https://matrix-aida.com/

箱罠

箱罠

くくり罠

くくり罠

パーツ類

パーツ類

電気柵

電気柵

自作キット

自作キット

防獣グッズ

防獣グッズ

監視カメラ

監視カメラ

box trap

box trap

tying trap

tying trap

enclosure trap

enclosure trap

Prevention and avoidance goods

Prevention and avoidance goods

electric fence

electric fence

trap surveillance camera

trap surveillance camera

transportation goods

transportation goods

Trap detection sensor

Trap detection sensor

hunting supplies

hunting supplies

hunting books

hunting books

Anti-bird goods

Anti-bird goods

Agricultural materials/machinery

Agricultural materials/machinery

boar

boar

deer

deer

Kyon

Kyon

monkey

monkey

raccoon

raccoon

Badger

Badger

palm civet

palm civet

raccoon dog

raccoon dog

nutria

nutria

mouse or rat

mouse or rat

Mole

Mole

bear

bear

pigeon

pigeon

Crow

Crow